The core advantages of cement tank trailers (bulk cement semi-trailers) can be summed up in one sentence: "high loading capacity, fast unloading, labor saving, and value preservation." They are specifically reflected in the following five dimensions:

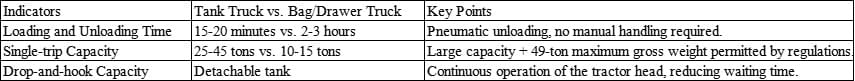

✅ 1. Transportation efficiency advantage

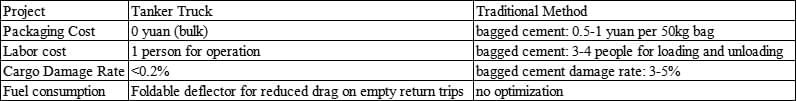

✅ 2. Cost advantage

✅ 3. Environmental protection and policy advantages

- Dust-free operation: A fully enclosed tank with a top-mounted dust collector meets urban environmental protection requirements (e.g., Beijing and Shanghai prohibit the import of bagged cement).

- Lightweight and compliant: Aluminum alloy tanks can reduce weight by 1.5-2 tons, directly translating into additional cargo capacity.

- New energy adaptability: Some manufacturers have launched electric tractor + aluminum alloy tanker combinations (e.g., BYD T31 + CIMC tank).

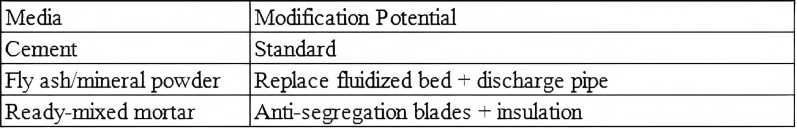

✅ 4. Multi-scenario adaptability

✅ 5. Residual value and asset preservation

- Secondhand market premium: A five-year-old aluminum alloy tanker still has a residual value of 45-50% (compared to 30% for standard flatbed trucks).

- Reuse: The tank can be converted into a dry-mix mortar truck or bulk grain truck, extending its lifespan.

⚠️ Note: The premise of advantage

- Applicable scenarios: Trunk transport over 200 km, and areas with concentrated concrete mixing plants.

- Not suitable for: Remote mountainous areas (without a gas source) or frequent overloading (where the tank has limited pressure).

✅ Summary in one sentence

"The essence of a cement tank trailer is a 'mobile bulk cement warehouse'. It compresses the three steps of packaging, loading and unloading, and transportation into one action. This is the real secret of its crushing performance over bagged transportation."