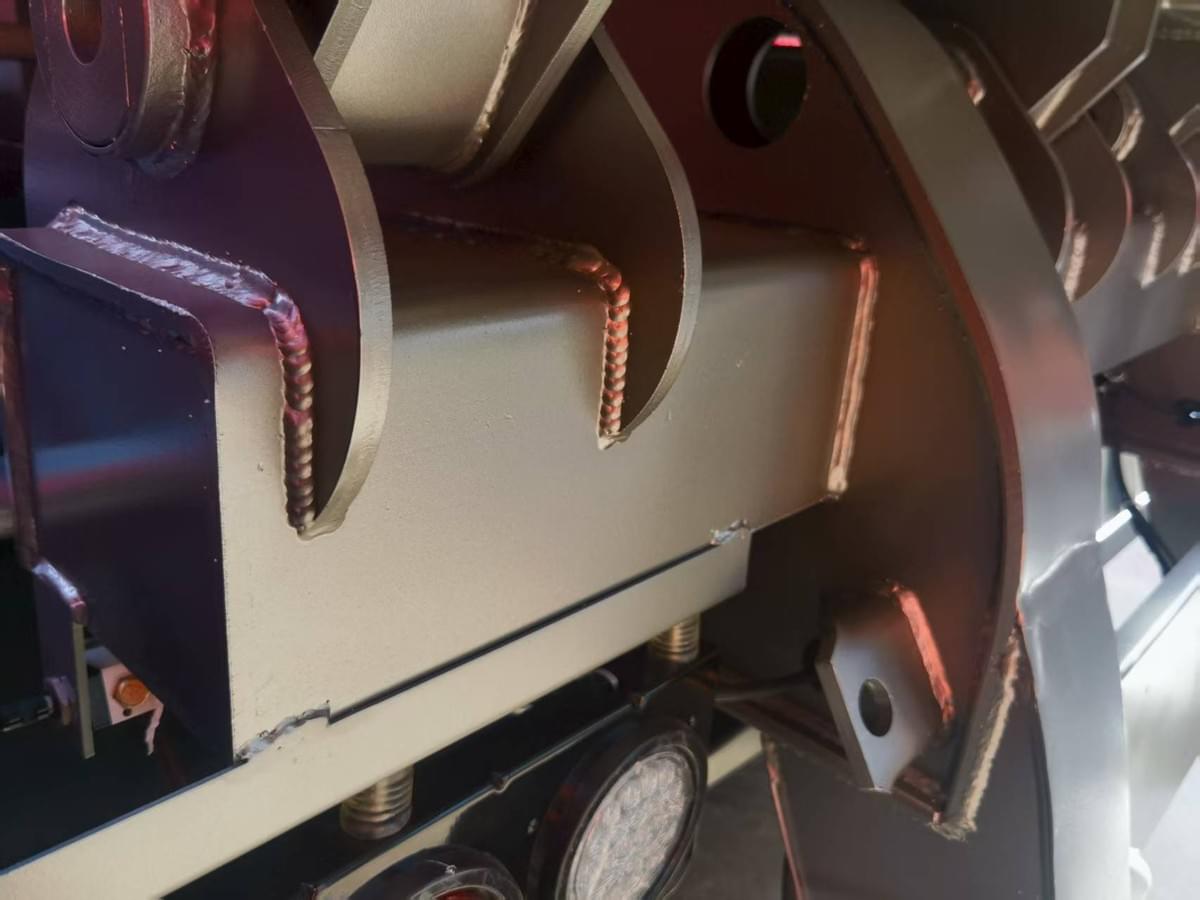

In the industrial welding field, fish-scale welding has long been considered a sophisticated and artistic technique. It requires not only weld strength and sealing, but also aesthetics and uniformity. Fish-scale welding is named for its unique fish-scale texture, which not only enhances the weld's aesthetic appeal but also strengthens its strength and toughness.

1. Characteristics of Fish-Scale Welding

(1) High Welding Quality

The layered structure of fish-scale welding significantly enhances the weld's mechanical properties. Its uniform fusion reduces defects such as porosity and cracks, improving fatigue resistance and corrosion resistance. This welding method is particularly suitable for applications requiring extremely high reliability, such as aerospace, shipbuilding, and pressure vessels.

(2) Balancing Aesthetics and Functionality

The fish-scale texture is not only a reflection of craftsmanship but also a form of "industrial aesthetics." In welding competitions, fish-scale weld texture uniformity, excess height (0-2mm), and surface smoothness are important evaluation criteria. This aesthetically pleasing weld not only improves the product's appearance but also reduces the need for post-processing.

(3) Technical and Economic Advantages

Fish-scale welding produces smooth weld surfaces, meeting acceptance requirements without additional polishing. Furthermore, by adjusting the oscillation pattern (such as zigzag, crescent, or figure-eight), it can accommodate various groove angles and thicknesses. Welders who master fish-scale welding techniques can earn top-tier salaries in the industry, and market demand is strong.

2. Technical Difficulty of Fish-Scale Welding

Fish-scale welding is relatively technically challenging, primarily in the following aspects:

(1) High Skill Requirements

Welders must master precise welding parameters, including welding current, voltage, and speed, to ensure weld quality and aesthetics. Maintaining a steady hand during welding is crucial to avoid shaking and burning the tungsten electrode, which can lead to tungsten inclusions in the weld pool.

(2) High Requirements for Welding Material Selection and Processing

Different welding materials require different welding processes and parameters, as well as rigorous pretreatment of the materials, such as decontamination and rust removal.

(3) High Requirements for Welding Environment Control

Fish-scale welding requires a relatively stable welding environment to avoid various defects such as porosity and slag inclusions during welding.

3. Applications of Fish-Scale Welding

Due to its high quality and aesthetics, fish-scale welding has been widely used in a variety of fields:

(1) Aerospace

In the aerospace field, fish-scale welding is used to manufacture key components of aircraft, rockets, and other aircraft to ensure high strength and sealing.

(2) Shipbuilding

In shipbuilding, fish-scale welding is used to weld hull structures to improve the strength and durability of ships.

(3) Bridge Construction

In bridge construction, fish-scale welding is used to weld key parts of bridges to ensure their stability and safety.

(4) Artistic Decoration

In addition to industrial applications, fish-scale welding is also used in artistic decoration, such as in the creation of sculptures and artworks, showcasing its unique beauty and craftsmanship.

4. Future Development Trends of Fish-Scale Welding

With the continuous advancement of science and technology, welding technology is also constantly innovating and advancing. For example, the application of laser welding technology in fish-scale welding makes the welding process more precise and efficient. Laser welding, through its high-energy beam focusing and rapid cooling, significantly surpasses traditional welding processes in terms of fish-scale aesthetics, uniformity, and weld quality. The emergence of this technology not only improves welding efficiency but also reduces production costs.

5. Summary

As an advanced welding technique, fish-scale welding has extensive applications not only in industry but also demonstrates its unique value in artistic decoration. Although technically challenging, with technological advancements and the emergence of new processes, the scope of fish-scale welding's applications will further expand. In the future, we can expect fish-scale welding to play a vital role in even more fields, bringing greater possibilities to industrial production and artistic creation.